Advancing Manufacturing with Aluminium CNC Machining

Introduction to Aluminium CNC Machining

Aluminium cnc machining has revolutionized modern manufacturing by combining the versatility of aluminium with the precision of computer-controlled machinery. This process allows manufacturers to produce components that are lightweight, durable, and highly accurate. Industries such as aerospace, automotive, electronics, and medical technology increasingly rely on aluminium cnc machining to meet high standards of performance and reliability.

The automation provided by CNC (Computer Numerical Control) technology ensures consistent production quality and repeatability. With the ability to handle complex geometries and tight tolerances, aluminium cnc machining is an essential solution for both prototype development and large-scale manufacturing.

Benefits of Aluminium CNC Machining

Lightweight and High Strength

Aluminium cnc machining provides components that are light yet structurally strong. This combination is particularly valuable in sectors like aerospace and automotive, where reducing weight enhances efficiency without compromising safety. Lightweight aluminium parts also contribute to lower energy consumption and better overall system performance.

Precision and Accuracy

CNC technology enables the production of aluminium components with extreme precision. Tight tolerances ensure proper fit and function, while the repeatability of CNC machining guarantees uniformity across production batches. This precision reduces assembly errors and enhances product reliability.

Corrosion Resistance

Aluminium naturally resists corrosion, making it suitable for environments exposed to moisture or harsh chemicals. Aluminium cnc machining ensures that components maintain their structural integrity and performance over time, minimizing maintenance requirements.

Thermal and Electrical Properties

Aluminium’s thermal and electrical conductivity makes it ideal for applications such as electronic housings, heat sinks, and power distribution components. CNC machining ensures parts are accurately shaped to maximize performance while meeting design specifications.

Industrial Applications

Aerospace Applications

Aluminium cnc machining is critical in aerospace manufacturing. Components such as structural supports, engine parts, brackets, and housings benefit from aluminium’s lightweight and strong properties. Precision machining ensures compliance with strict aviation standards while reducing overall aircraft weight.

Automotive Industry

Automakers use aluminium cnc machining for engine parts, suspension elements, and structural components. Reducing vehicle weight improves fuel efficiency and handling, while CNC precision guarantees reliable performance and accurate assembly.

Medical Devices

The medical industry requires components with high precision and strict adherence to tolerances. Aluminium cnc machining produces surgical tools, diagnostic equipment housings, and electronic medical device components. CNC machining ensures consistency and accuracy, essential for patient safety and device reliability.

Electronics and Consumer Goods

Aluminium cnc machining is widely used in electronic housings, heat sinks, and structural frames for consumer products. The material’s lightweight and conductive properties improve thermal management and durability. CNC technology allows the creation of intricate designs that enhance both functionality and aesthetic appeal.

See also: Tech Businesses Are Investing Billions on

The Aluminium CNC Machining Process

Selection of Aluminium Alloy

Choosing the right aluminium alloy is crucial for performance. Commonly used alloys include 6061, 7075, and 2024, each offering distinct characteristics in terms of strength, corrosion resistance, and machinability. The selection is based on application requirements and operating conditions.

Machining Techniques

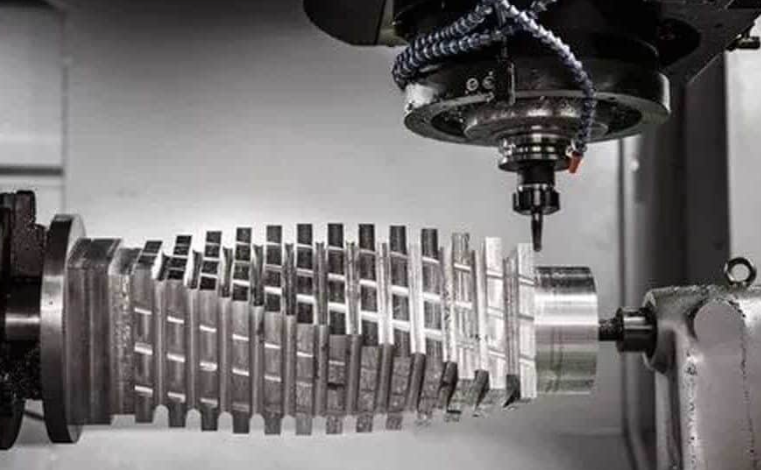

Aluminium cnc machining involves several core processes:

- Milling: Creates flat surfaces, slots, and complex shapes.

- Turning: Produces cylindrical and rotational components.

- Drilling: Ensures precise holes for assembly or functional requirements.

- Finishing: Polishing, grinding, and deburring improve surface quality and dimensional accuracy.

CNC systems control all operations with high precision, ensuring that each part meets exact specifications.

Quality Control

Quality assurance is critical in aluminium cnc machining. Measurements using coordinate measuring machines (CMMs), calipers, and micrometers verify dimensions, tolerances, and surface finish. This thorough inspection guarantees the reliability and performance of all components.

Design Considerations

Wall Thickness and Strength

Optimizing wall thickness ensures components remain strong while minimizing weight. Proper design prevents deformation and improves the long-term durability of parts.

Tolerance and Fit

Maintaining precise tolerances ensures that components fit accurately and function properly. CNC machining allows manufacturers to achieve these high standards consistently.

Surface Finish

Surface finish impacts both functionality and visual appeal. Smooth finishes reduce friction in moving parts and enhance the appearance of consumer-facing products.

Complexity Versus Cost

While CNC machining supports highly complex designs, intricate components may increase production time and cost. Manufacturers balance complexity and feasibility to produce high-quality parts efficiently.

Advantages Compared to Other Materials

Aluminium cnc machining offers a balanced combination of light weight, strength, and corrosion resistance. Steel is stronger but heavier and harder to machine, while plastic is lightweight but less durable and thermally stable. Aluminium provides a versatile solution suitable for a wide range of industrial and consumer applications.

Future Trends

Automation and Smart Manufacturing

Integration of AI, IoT, and automation in CNC processes improves production efficiency, reduces errors, and ensures consistent quality. Smart manufacturing allows faster and more cost-effective production of aluminium components.

Advanced Aluminium Alloys

New aluminium alloys with enhanced strength, corrosion resistance, and thermal properties expand the potential applications of cnc machining. These innovations support more demanding industrial requirements.

Sustainable Manufacturing

Sustainability is increasingly important in modern manufacturing. Recycling aluminium and employing energy-efficient machining processes minimize environmental impact while maintaining precision and performance.

Conclusion

Aluminium cnc machining is vital to modern manufacturing, offering lightweight, durable, and precise components. Industries such as aerospace, automotive, medical, and electronics depend on these components for reliable, high-performance solutions. With ongoing advancements in CNC technology, alloy development, and sustainable practices, aluminium cnc machining will continue to play a central role in shaping the future of industrial production.