Plastic Injection Moulding: What Buyers Need to Know

Plastic injection moulding is one of the most widely used manufacturing processes in the automotive industry. It allows for the mass production of durable, lightweight, and cost-effective components with high precision. For OEMs and suppliers, choosing the right plastic injection moulding manufacturer is critical to ensuring product quality, compliance, and scalability.

Experimental findings also confirm that higher mold temperatures and injection pressures can significantly affect product distortion and reliability, which is crucial for automotive manufacturers aiming to meet strict industry standards. This makes selecting a capable and experienced manufacturer more important than ever.

Here’s what every buyer should know before choosing a partner for plastic injection moulding:

Understanding the Process

Plastic injection moulding is a precise and highly efficient manufacturing technique widely used in the automotive sector. It transforms raw plastic into complex, durable components that meet strict performance and safety standards. Here’s a step-by-step look at how the process works:

Step 1: Material Preparation

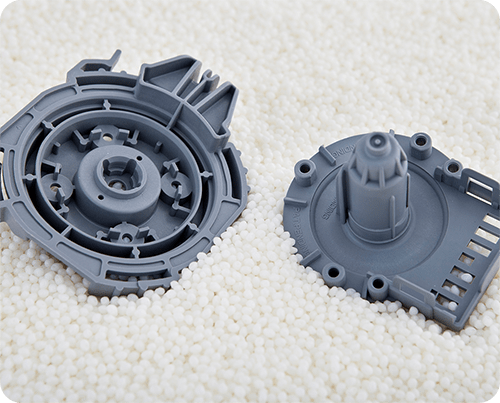

Plastic resin, usually in the form of pellets or granules, is dried and prepared to remove any moisture that could affect product quality. The choice of resin, whether polypropylene, ABS, nylon, or polycarbonate, depends on the component’s required strength, durability, and resistance.

Step 2: Melting the Plastic

The pellets are fed into a heated barrel, where they are melted using heaters and a rotating screw. Precise control of temperature at this stage is essential — too high can cause degradation, while too low may lead to incomplete filling.

Step 3: Injection into the Mould

Once melted, the plastic is injected under high pressure into a custom-designed mould cavity. The mould, typically made of steel or aluminum, determines the exact shape and features of the final product. Experimental findings show that injection pressure and mould temperature play a critical role in reducing distortion and ensuring dimensional accuracy.

Step 4: Cooling and Solidification

The molten plastic inside the mould cools and solidifies into the desired shape. Cooling systems built into the mould regulate temperature, ensuring even solidification and preventing warping or shrinkage. The cooling phase often takes the most time in the cycle.

Step 5: Ejection of the Part

Once cooled, the mould opens, and ejector pins push the solidified part out. At this stage, the component is inspected for defects such as warping, flash, or incomplete filling.

Step 6: Post-Processing and Quality Checks

The part may undergo additional finishing steps like trimming, surface treatment, or assembly. Rigorous quality checks ensure every component adheres to global automotive safety and performance standards before being approved for OEM use.

Why This Matters for Buyers?

Understanding the injection moulding process helps buyers evaluate a manufacturer’s capabilities. A reliable plastic injection moulding manufacturer not only has advanced machinery but also expertise in managing critical variables like temperature, pressure, and cooling, factors that directly affect part reliability, safety, and compliance.

What Else Buyers Should Consider?

Beyond understanding the plastic injection moulding process itself, buyers should also evaluate broader factors that impact reliability, cost-efficiency, and long-term partnerships. Here are key aspects to keep in mind:

1. Tooling and Mould Design Expertise

A high-quality mould is the foundation of consistent parts. Manufacturers with in-house tooling and design capabilities can ensure faster turnaround times, better precision, and easier modifications when product updates are needed.

2. Prototyping and Testing Support

Before committing to mass production, prototyping services allow buyers to test materials, dimensions, and functionality. Manufacturers that offer rapid prototyping and simulation tools reduce risks of costly redesigns later.

3. Customization Capabilities

Automotive parts often require unique specifications for different OEMs. A dependable supplier should be flexible in offering custom moulding solutions rather than only standard parts.

4. Supply Chain & Logistics Support

Smooth delivery is as important as manufacturing. Reliable plastic injection moulding manufacturers maintain robust logistics networks to ensure on-time delivery both locally and internationally.

5. After-Sales Service and Support

Long-term partnerships depend on responsiveness. Manufacturers that provide ongoing technical support, maintenance of moulds, and transparent communication help OEMs avoid downtime and delays.

Why Jairaj Group Stands Out

When it comes to selecting a trusted plastic injection moulding manufacturer, the Jairaj Group has built a strong reputation among global OEMs. With advanced manufacturing facilities, certified compliance, and a focus on sustainable innovation, the company delivers high-quality components that meet international standards.

Key Advantages of Jairaj Group:

- ISO-certified production and rigorous quality checks

- Scalable infrastructure for high-volume orders

- Expertise in material selection and custom moulding solutions

- Long-term partnerships with leading automotive brands

Final Words

For buyers, choosing the right plastic injection moulding manufacturer is about more than sourcing parts; it’s about ensuring long-term reliability, compliance, and innovation. By focusing on material expertise, certifications, scalability, and sustainability, businesses can make informed decisions that strengthen their supply chains.

With its proven track record and commitment to excellence, the Jairaj Group remains a trusted choice for OEMs worldwide, delivering precision-driven plastic moulded components that meet the demands of a rapidly evolving automotive industry.